D-Series

A full range of fully Servo controlled horizontal stand-up pouch packaging machines designed by PFM.

D-Series Range

A full range of models to cover all the needs for an extremely fast flexible packaging

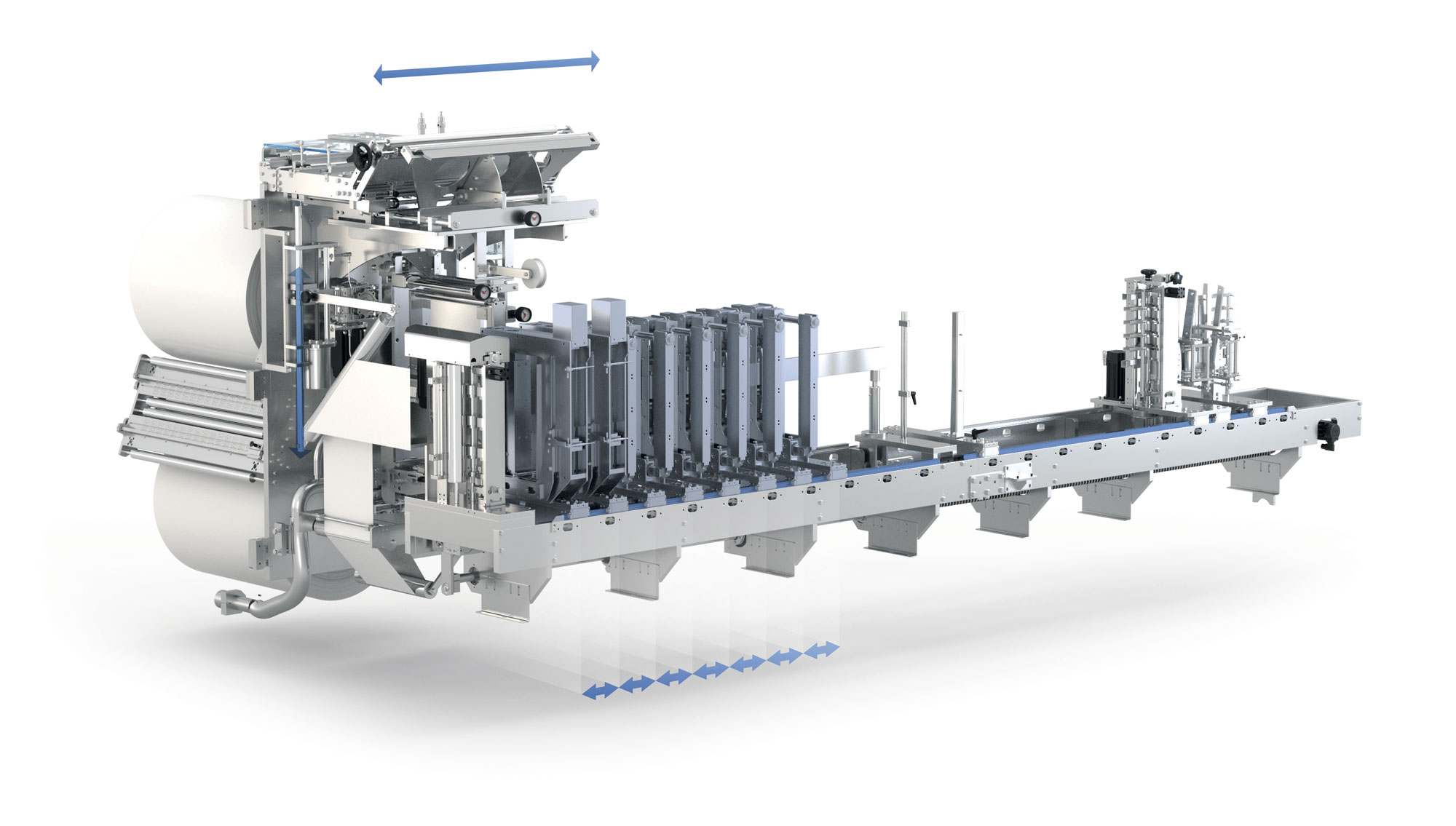

PFM D180 Simplex

Horizontal Form Fill Seal Pouch machine to produce up to 80 stand-up pouches per minute.

![]()

Max 180×300 mm.

Horizontal Form Fill Seal Pouch machine to produce up to 70 stand-up pouches per minute (Simplex) and up to 140 (Duplex).

![]() Simplex version 240×300 mm.

Simplex version 240×300 mm. Duplex version 120×300 mm.

Duplex version 120×300 mm.

Horizontal Form Fill Seal Pouch machine to produce up to 120 stand-up pouches per minute.

Max pouch dimensions 200×300 mm. (Base x Height)

Duplex version to produce up to 120 stand-up pouches per minute and the Triplex to produce up to 180 stand-up pouches per minute.

240×300 mm. (Duplex)

240×300 mm. (Duplex) 146×300 mm. (Triplex)

146×300 mm. (Triplex)

PFM D-EPT Series Simplex, Duplex or Triplex with the Same Machine

Up to 60 (Simplex), 120 (Duplex) and 180 (Triplex) stand-up pouches per minute.

Simplex

Simplex Duplex

Duplex Triplex

Triplex

Simple

Simple

The D-Series is simple because all functions and operations are precisely controlled, parameterized and repeatable, including:

- Automatic film stretch control & compensation.

- Sealing parameters are material driven, not speed dependent.

- Fast format change: takes 20 minutes on average.

- Low-tension film transport.

- Indicates time left before the end of the reel.

- Machine is easily accessible, can be sanitized and inspected.

Modular

Modular

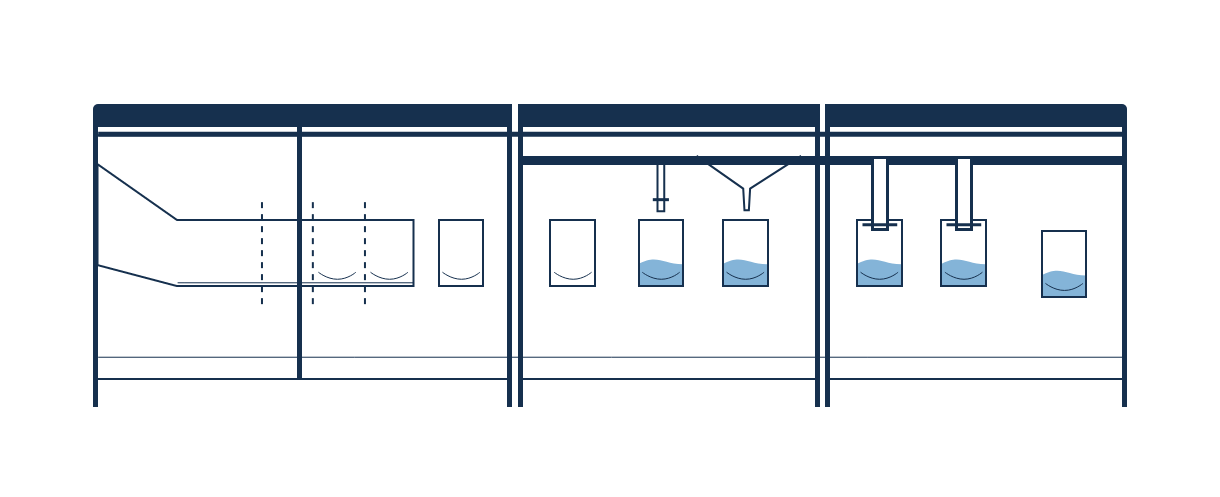

Each D-Series base machine features 3 areas that can be set-up independently during the format change. The pouch is opened, checked, filled with product, gas flushed (if necessary), sealed and cooled.

Forming

Forming

Forming Area takes the material from the reel, forming the pouch up to the cutting stage; in other words until the pouches are separated.

Filling

Filling

In the Filling Area product is dosed, filling the pouches.

Sealing

Sealing

The Sealing Area transports the pouch without releasing it until the packaging process is completed.

The machine can be enhanced by integrating the following modules: Check-weigher, Metal detector, X-Ray, Secondary Packaging.

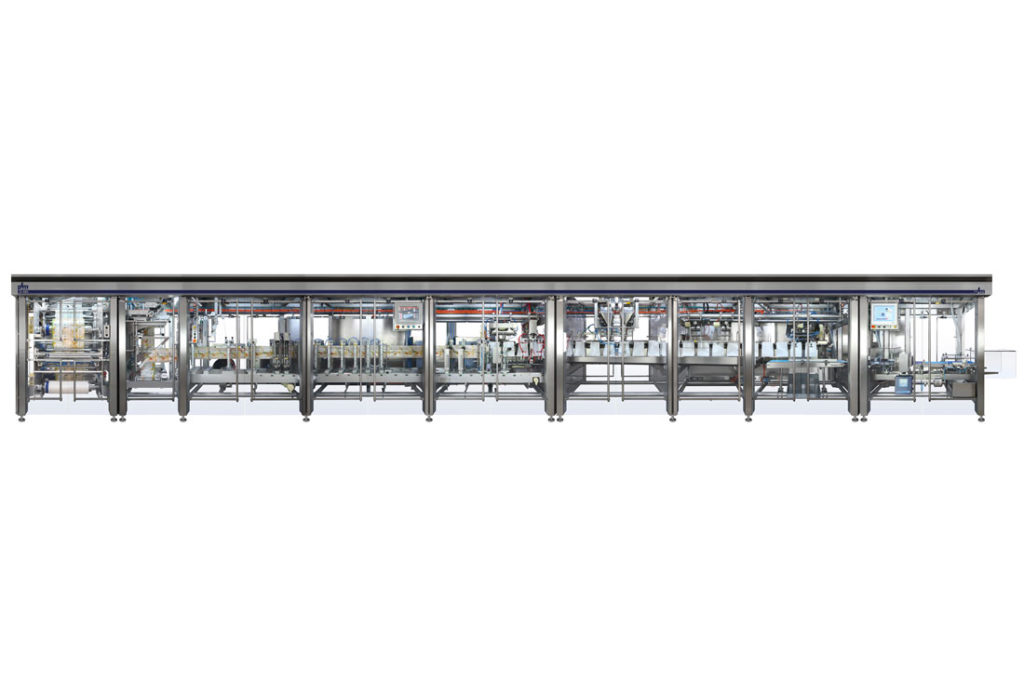

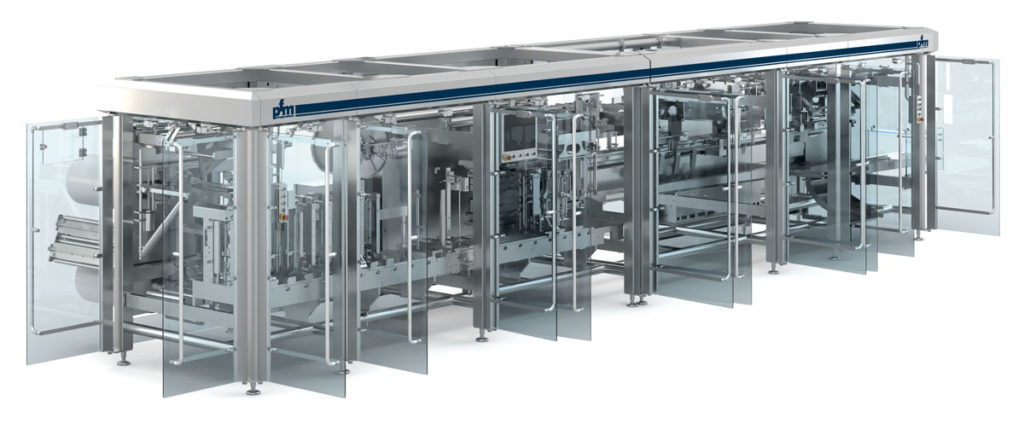

Accessible

Accessible

360º access to all mechanical and electronic components, enhanced ergonomics and supreme cleanability

We created a machine with a “portal” build concept. The entire machine is supported by the structural frame and protected by full height doors which give 360º access to all the mechanical and electronic components of the machine. As a result, operators can quickly and easily access the machine without having to remove guards.

Ergonomics are further enhanced with mechanisms located at a comfortable working height and exceptional floor clearance completes the supreme cleanability from top to bottom.

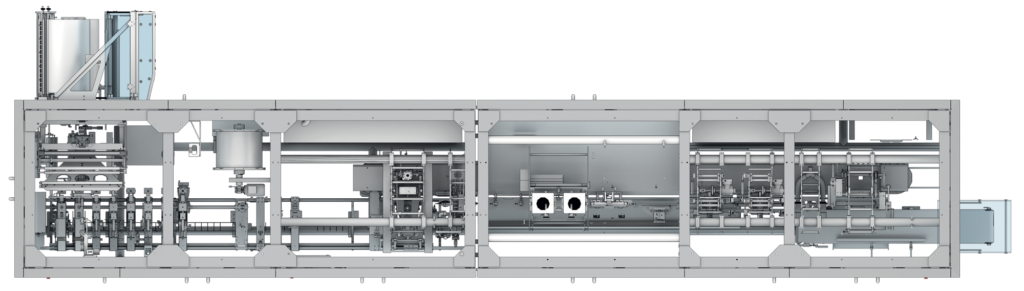

Compact

Compact

The PFM D-Series features a space-saving 90° reel holder assembly layout.

The film unwinder, reel-holding shaft, compensating device, printer adjustment system and the gusset punch dies are located at the back of the machine.

This arrangement significantly reduces the overall machine length. Electrical cabinets are integrated in the machine frame to reduce overall installation width and avoid cable trays crossing walkways. “Mirror” right-left configuration is available in all models offering additional flexibility for difficult spaces or shared operator zone for multi-machine installations.

Fast Format Change

Fast Format Change

Complete format changes in minutes, not hours thanks to a highly automated, tool-less procedure with no clean-down required before changeover.

Pouch formats selected from HMI menu, pouch transport grippers reposition in seconds, automated positioning of module A assemblies, including: sealing jaws, tear notch & corner rounding units, knives and material pulling rollers. Automated reel edge alignment. Minimal change parts with “Single Minute Exchange of Dies” concept. Fast ramp-up to full production with HMI-driven adjustments. Intelligent interface suggests positions for new formats.

Fully automatic option for “K” base seals. Optional automatic reel splicing.

High Productivity OEE

High Productivity OEE

The all in one conveyor system transports and firmly holds the pouches in order to ensure maximum operational safety.

The film-stretch control, sealing pressure, unit acceleration and reel-end prediction system are just some of the software features making the operator’s job easier permitting constant monitoring of all functions. The OEE index (Overall Equipment Effectiveness) is the verifiable scale of high performance created by the whole set of features included in the D-Series machine.